Characterize Coatings, Lubricants, Materials, and More

Rtec Instruments provides testing solutions for mechanical and optical surface characterization. Our innovative solutions cover tribology, scratch testing, adhesion, hardness, surface inspection, and more.

Tribology Testing

Examine friction, wear, or material properties under a variety of environments with accurate and reliable results.

Scratch & Indentation Testing

Measure mechanical properties, such as hardness, modulus, scratch adhesion, film thickness, and surface roughness.

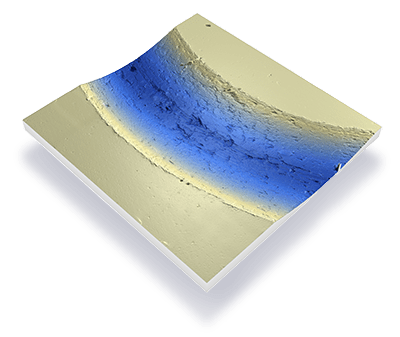

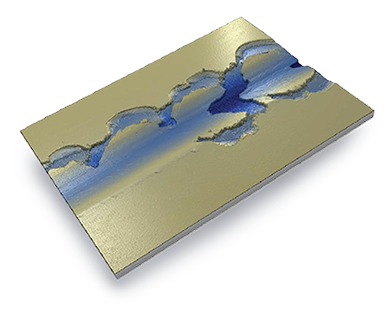

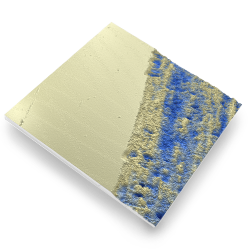

Surface Inspection

Combine many optical imaging techniques on one platform to measure roughness, step height, texture, geometry, thickness, and more for any material

Explore Our Product Highlights

We provide a mechanical and surface testing instrument for every application.

Universal MFT-5000 Tribometer

The MFT-5000 is globally regarded as the most versatile and advanced tribometer. In particular, the interchangeable test modules and environmental chambers provide several tests on the same platform.

Traction Testing

Revolutionize your traction testing with our mini and extreme traction machines. Built with versatility in mind, our traction machines offer the widest range of load, speed, environmental, and electrified conditions.

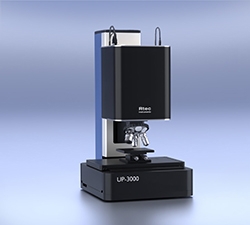

Indentation and Scratch Tester

Meet Rtec Instruments’ next-generation indentation, scratch adhesion, and hardness tester, The SMT-5000. It is one powerful platform for the nano, micro, and macro test range with the patented integrated high-resolution 3D profiler.

3D Universal Profilometer

The 3D Universal Profilometer is an optical 4 in 1 surface inspection system. In fact, it works across any surface – transparent, opaque, rough, or smooth. Get a perfect surface profile every time at nm resolution and high speed.

Want to learn more?

Get in touch, and request a demo.

recommended

Information

© Copyright 2021 Rtec-Instruments - All Rights Reserved