Equipping Innovation

With over 34 years of excellence in manufacturing, AJA International, Inc. is fueling a global golden age of innovation in the world of thin film coating & deposition.

WELCOME TO AJA INTERNATIONAL, INC.

AJA is a manufacturer of thin film deposition systems including magnetron sputtering, e-beam evaporation, thermal evaporation, and ion milling systems. Founded in Scituate, MA, USA in 1989 by William Hale, MBA, BS Physics, the company was established as a supplier of innovative physical vapor deposition (PVD) products. With many systems and magnetron sputter sources shipped worldwide, AJA International, Inc. continues to discover innovative design solutions which are often copied but never equaled. The company truly remains the cutting edge in thin film technology.

SPUTTERING

SYSTEMS

ION MILLING

SYSTEMS

HYBRID

SYSTEMS

EVAPORATION

SYSTEMS

SPUTTERING

SOURCES

SUBSTRATE

HOLDERS

WHAT’S NEW AT AJA

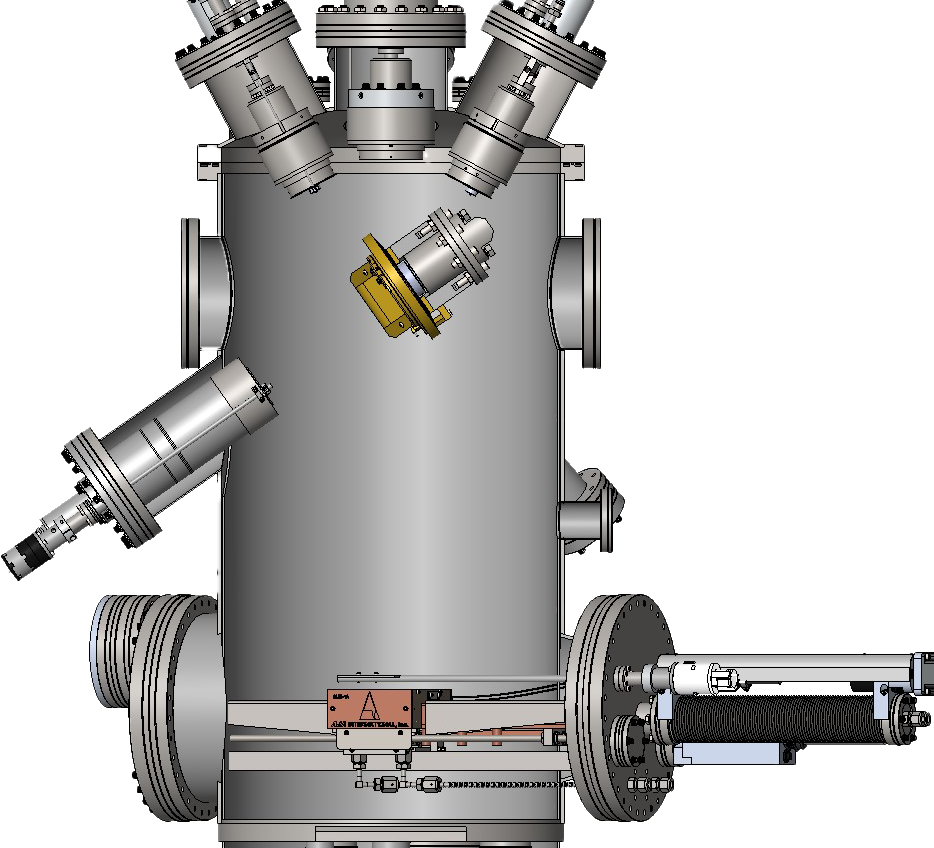

The ATC-1800 UHV Electron Beam Evaporation System with Load-Lock and Appendage Chamber

This ATC-MC Multi-Chamber System has a unique combination of capabilities. The main deposition chamber includes a UHV 6-Pocket 15cc Linear Electron Beam Gun, and 4” motorized tilting (+/- 180 degrees) substrate holder with LN2 cooling capabilities. The load-lock system at natural static oxidation capabilities ranging between 5-100 Torr.

The custom appendage chamber has sample cleaning and analytical capabilities. For sample cleaning the chamber is equipped with substrate heating to 850C for sample degas, and a Hydrogen Atom Beam Source (HABS). The HABS is a thermal gas cracker that produces an absolutely ion-free hydrogen gas beam, avoiding ion induced damage to the substrate. For analytics the chamber is equipped with a HIDEN Temperature Desorption Probe (TPD/TDS). The TDS includes a triple filter mass analyzer configured with a cooled shroud giving the analyzer optimum sensitivity with minimum background contributions to accurately read contaminates being desorbed from the sample surface. In addition, the chamber is equipped with a RHEED and AUGER system from STAIB Instruments. When used in combination this will provide a wealth of complementary structural and chemical information to optimize thin film fabrication and better control of material properties.

WHAT’S NEW AT AJA

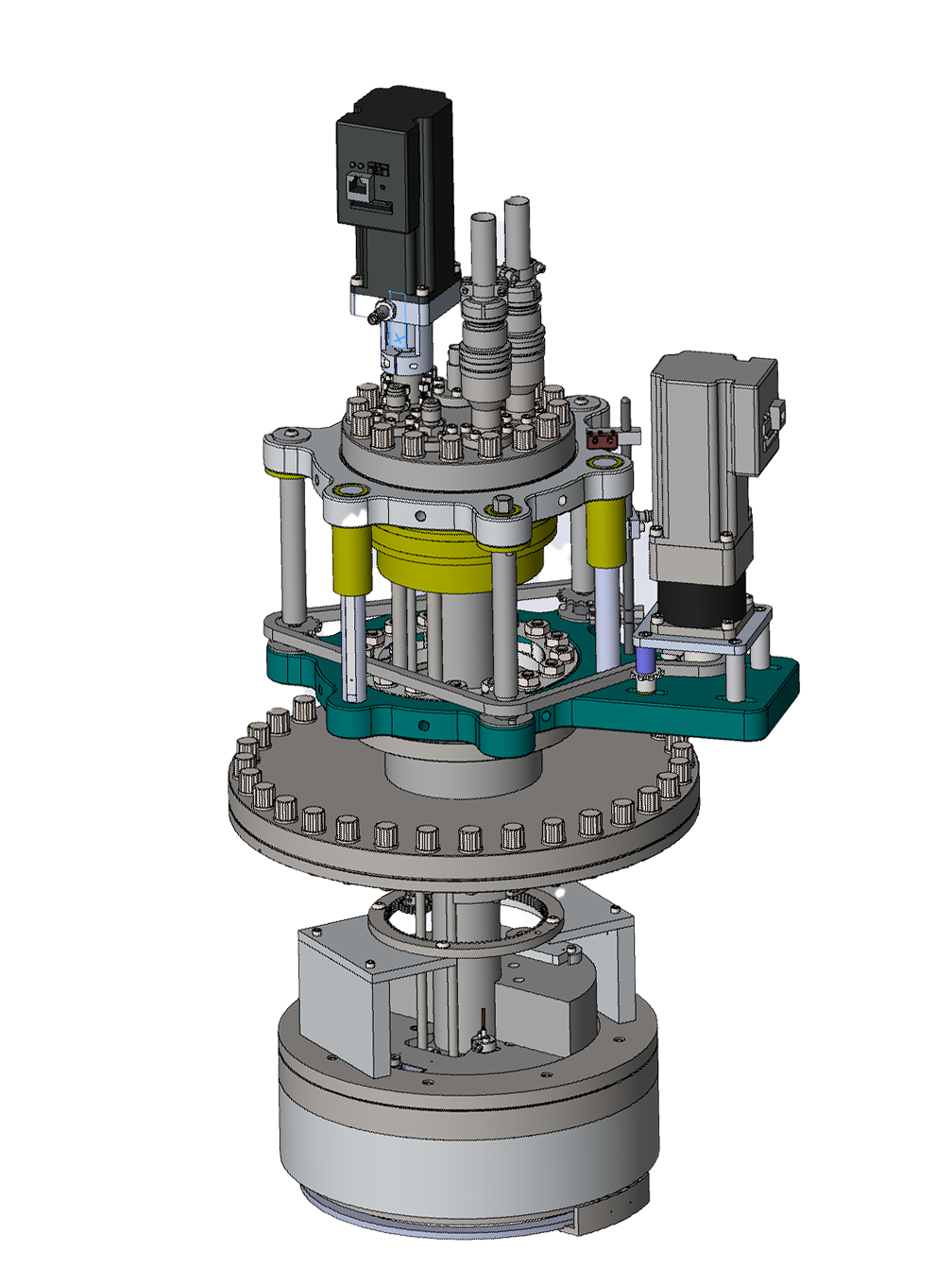

ATC-MC Multi-Chamber Magnetron Sputtering System with Cassette Loading and Automated Transfer Capabilities.

The ATC-MC Multi-Chamber Magnetron Sputtering System allows automated in-situ transfer between two UHV deposition chambers each equipped with (5) 3” con-focal sputtering sources, (1) 6” direct sputtering source, and (1) 4cm gridded DC ion source. Sputtering sources are powered by DC, RF, and HiPIMS generators.

System is designed for up to 8” wafer handling, 800C heating, 0-40 RPM azimuthal rotation, RF/DC biasing, and 100mm z-motion adjustment. Additional features include custom bakeout jacket for chamber conditioning (< 9.0x10-10 Torr), turbo/cryo pump combination, automated crystal monitor positioning for rate calibration and data logging, and post wafer cooling via He gas.

WHAT’S NEW AT AJA

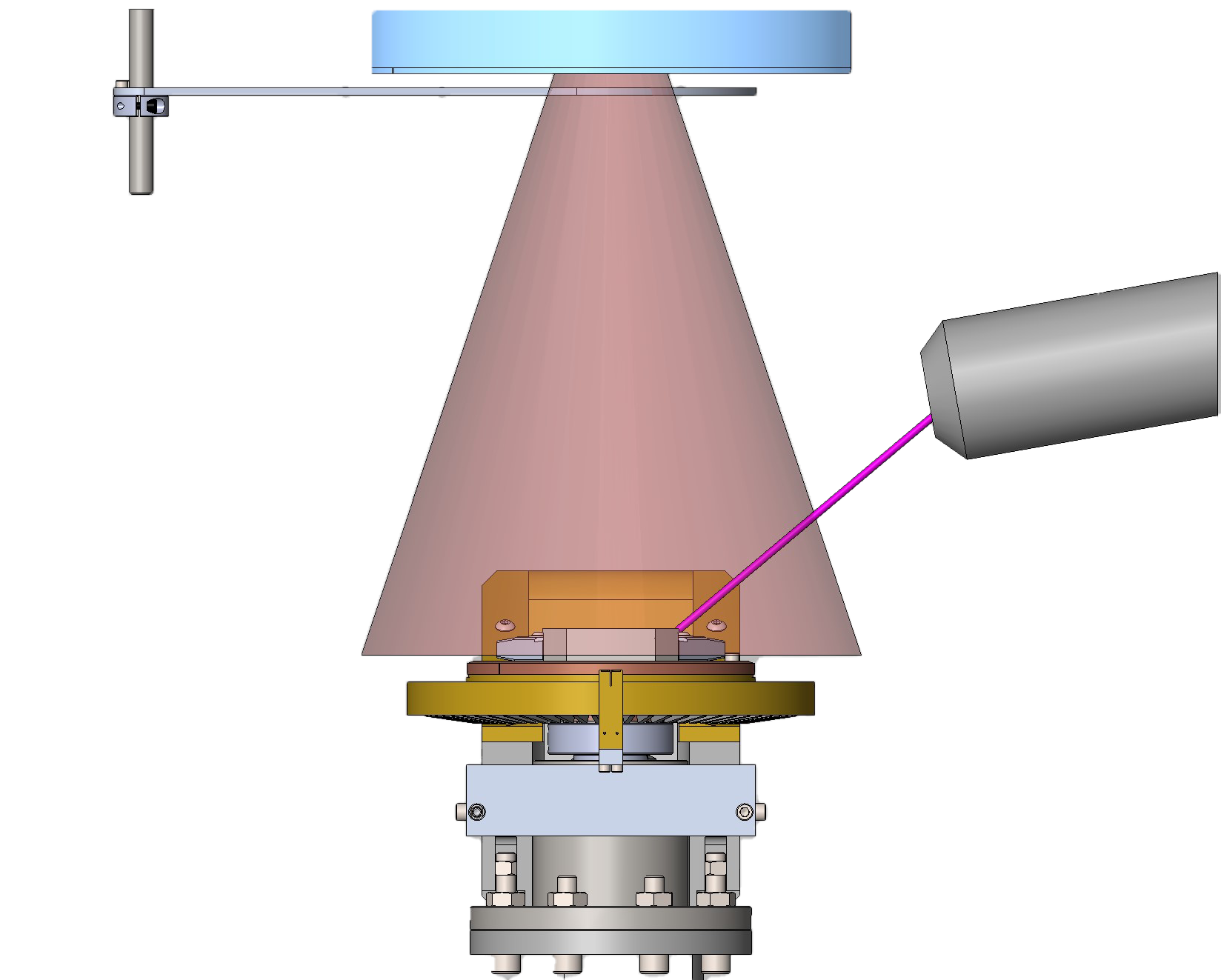

ATC-2200-HY UHV Hybrid Deposition System with XPS integration

The ATC-2200-HY Hybrid Deposition system is equipped with (5) 2” con-focal sputtering sources, (1) 3” direct sputtering source, (1) 6-pocket 15cc linear electron beam gun, and (1) 4cm gridded DC ion source. The system is designed to accommodate up to 3” wafer handling, 850C heating, azimuthal rotation, RF/DC biasing, 100mm z-motion, and in-situ mask exchange mechanism. In addition the system has an appendage chamber that allows the user to disengage the mask, flip the substrate 180 degrees, and in-situ transfer into an XPS system for chemical and elemental analysis.